Liner Fixing & Sealing Machinery

Special Purpose Packaging Machines for Wadding, Sealing & Assembly of Liners, Gaskets & Plastic Components.

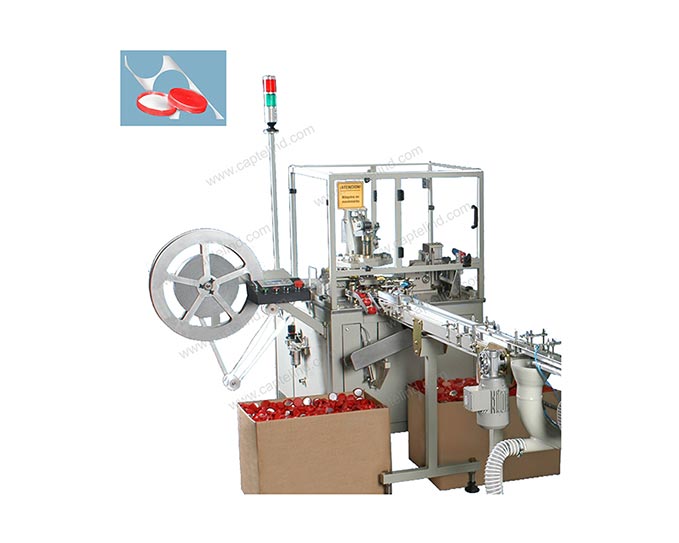

Wadding Machines for Fixing Liners in Closures

Machine Introduction

We offer arange of high-speed Machines capable of fixing liners automatically in Plastic Closures.

This machine is capable of inserting and fixing the wads into the Caps. The Caps will be loaded into a Hopper manually, then the feeder supplies these Caps adequately as required to the machine in the oriented fashion. The conveyor transfers the Cap to a starwheel where the Caps are indexed at predefined locations. The wads are loaded into a column chute (if in rolls) or into a vibratory feeder (if loose packed liners, normally for EPE Foam liners) which is placed above the wad picking station. A vacuum picker assembly is placed below the column chute which picks the wad one by one and places on the top portion of the indexing starwheel above the Caps. When the Cap and the Wad moves to the next station a pusher pushes the wad into the cap and is firmly fixed. The assembled cap will be counted and will exit from the conveyor. The machine will be capable of handling various types and sizes of caps and wads with the help of change parts.

Available with or without Hot Gluing System

Speeds Available – 60, 120 , 200 , 300 & 400 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners (in pre-cut and Roll form)

Wadding Machines for Cutting & Fixing Liners in Closures

Machine Introduction

This machine is capable of Cutting Liners from Rolls and inserting and fixing these cut wads in to the caps in a single operation.

The machine is capable of Cutting Liners from Rolls and inserting and fixing these cut wads into the caps in a single operation. The caps will be loaded into a Vibratory hopper or Elevator Hopper manually. The feeder supplies the caps adequately as required to the machine in the oriented fashion. The conveyor transfers the cap to a dial where the caps are indexed at predefined locations. The Liners in Rolls are fed onto the In - feed rollers and cut just in time before the wad punching station. The Liner drops into the Cap and when the cap and the wad moves to the next station a pusher pushes the wad into the cap and is firmly fixed. The assembled cap will be counted and will exit from the conveyor. The machine will be capable of handling various types and sizes of caps and wads with the help of change parts.

Available with or without Hot Gluing System

Speeds Available – 60 and 120 Caps per minute

Suitable for use with Two piece or One piece Liners and EPE liners